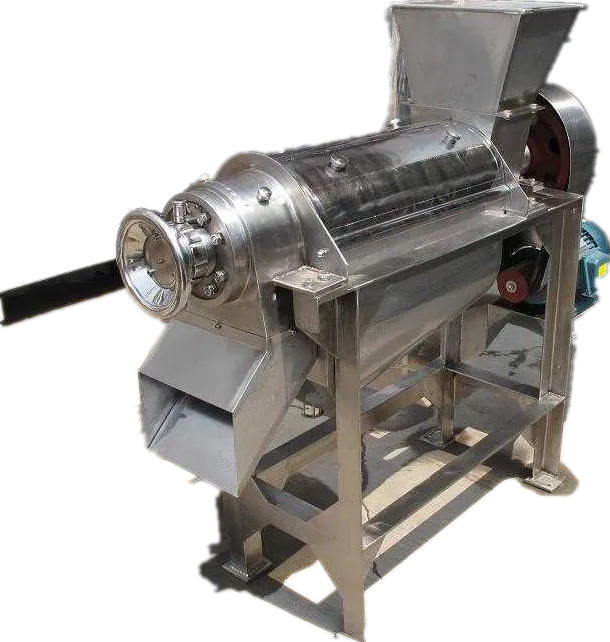

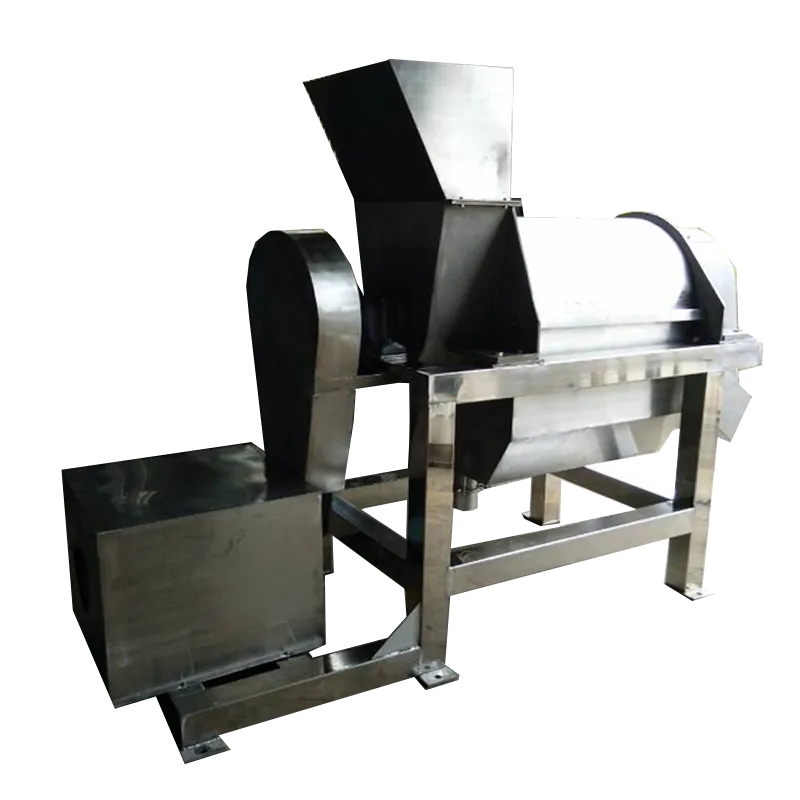

Industrial ginger juicer extractor machine

1.Machine introduction of Commercial Juicer Extractor Machine:

This Industrial Juicer machine is applicable to be juicing various fruits, such as tomato, pineapple, apple and orange etc. It has the following features:

(1).screw propelling and extruding;

(2).Slag discharge part improved, suitable for pressing high-fiber materials such as leaf vegetables etc;

(3).Automatically finish the processes of juicing and slagging for fruits and vegetables, such as berries and pome fruits etc.

Main structure principle of Commercial Juicer Extractor Machine:

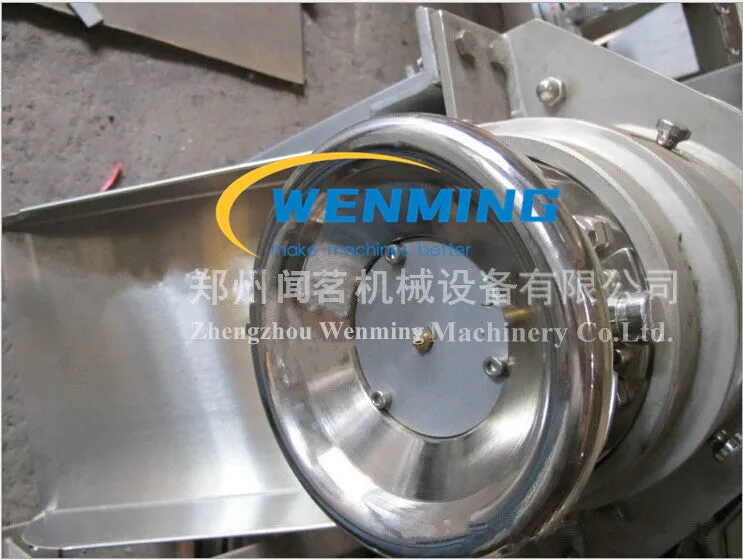

The main component is to nuclear pulp, juice, leather through a pipe into the spiral juice machine, by screw, screw diameter along the bottom slag is expected to export direction gradually increase and pitch gradually reduce, when the material being spiral propulsion for spiral cavity volume shrinking, form for material crushing. Screw spindle rotation direction from the feed hopper to slag trough direction, as the clockwise direction. Raw material add to the feed hopper, under the propulsion of spiral compression, the squeezing the juice through a filter at the bottom of the gravy, while the waste and the conical part of the surge tank by screw formed between the annular gap discharge, pressure regulating head along the axial movement of adjustable gap size. From the slag trough of equipment used in clockwise (to the feed hopper depending on the rotation handwheel bearing seat, regulating the head to the left, the gap is narrowing, conversely gap bigger.) Change the size gap, changing the resistance of slag discharge, can change the rate of slag, but if the gap is too small, the strong pressure, part of slag particles with juice by filter out, although the juice increased, but the quality of juice relative decline, the size of the gap should be depending on the user's specific technical requirements. Achieve the goal of separating juice and residue automatically.

Industrial Juicer Machine structure diagram

2. Technical parameters of Commercial Juicer Extractor Machine

|

Model |

WM-LZ-0.5 |

WM-LZ-1.0 |

WM-LZ-1.5 |

WM-LZ-2.5 |

LZ-5.0 |

|

Capacity |

300-500kg/h |

800-1000kg/h |

1200-1500kg/h |

2000-2500KG/H |

5000kg/h |

|

voltage/frequency |

1.5KW |

2.2KW |

4KW |

15KW |

30KW |

|

Spiral diameter |

φ88mm |

φ125mm |

φ175mm |

φ250mm |

φ400mm |

|

Filter aperture |

0.6mm |

0.6mm |

0.6mm |

0.6mm |

0.6mm |

|

Dimension |

780*320*860mm |

880*330*900mm |

1300*520*1300mm |

1500*670*1720mm |

2600*950*1900mm |

|

weight |

75kg |

114kg |

240kg |

440kg |

1300kg |